- In-wheel motor maker Elaphe would not see points with sturdiness or unsprung mass

- “Car-level” integration of tech might deliver 20% cheaper automobiles, 20% effectivity increase

- Elaphe is focusing on 95% effectivity on a battery-to-wheel foundation by 2030

In the event you took a fast have a look at the show stand for Slovenia’s Elaphe Propulsion Applied sciences at CES 2025 final month, you might need walked away with the message that the provider of in-wheel motors has moved on from Aptera, Lightyear, and Lordstown and is pitching its tech to vehicles which are quick, unique, and costly.

That a lot is true—within the quick time period. Lengthy-term, Elaphe has a grander world imaginative and prescient than simply becoming into the efficiency image.

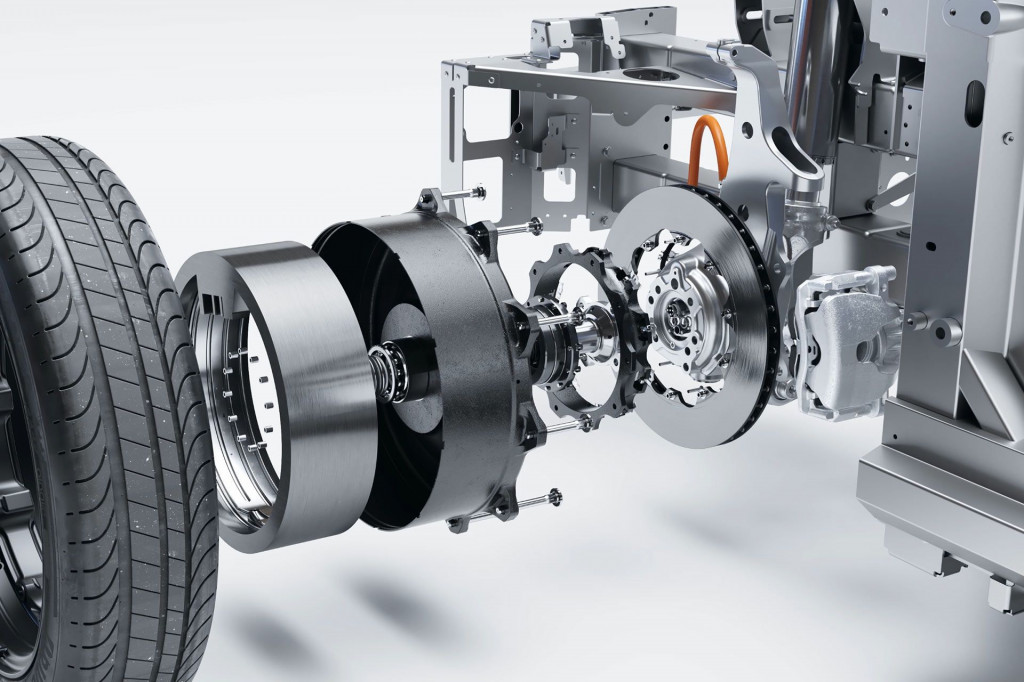

Within the meantime, it sees efficiency automobiles as the right venue for exhibiting tech-savvy automotive patrons what in-wheel motors can do. At CES, Elaphe revealed a revised in-wheel motor design, referred to as Sonic 1, that’s appropriate with bigger, track-ready brakes and high-performance automobiles.

In a rear-engine, rear-wheel-drive mannequin, as an example, it might ship “one thing further,” as model and advertising and marketing architect Iztok Franko put it, on the entrance wheels with out redoing the structure of the automobile—as a part of a hybrid efficiency improve.

Elaphe Sonic 1 in-wheel motor for efficiency vehicles. – CES 2025

The Sonic 1 motors themselves, which it teases are prone to arrive in a manufacturing automobile in 2026, could make as much as 268 hp and 737 lb-ft every of their default kind—designed to suit a 21-inch entrance wheel, as proven. And to take it to a scorching excessive, they’re being developed to suit as much as 24-inch wheels, as Elaphe and its stand companion Italdesign teased in an up to date Quintessenza supertruck idea, providing a hypothetical mixed max of 1,600 kw (practically 2,150 hp).

“So now we take away the impediment of reengineering the entire automobile, it’s simple to combine, and you may improve the efficiency and improve the management of the automotive,” mentioned Franko.

Italdesign Quintessenza idea

In-wheel tech guarantees simplicity, effectivity

In the event you examine it to an e-axle with an inboard motor, there are not any further mechanical losses, as a result of it’s just one rotating half per motor. There are not any further bearings, gears, or added fixed velocity joints, both.

It’s a great begin to eager about what in-wheel tech can do, and why it’s been common for some automobile sorts, like very massive vehicles and buses. But it surely’s solely scratching the floor for what Elaphe and the few different firms see as a brilliant future making use of the tech to passenger automobiles.

Inexperienced Automobile Studies caught up with Elaphe chief expertise officer Gorazd Gotovac at CES about how its expertise is evolving and located an organization that sees in-wheel tech as a key half within the long-term way forward for the automotive.

Gotovac emphasised to Inexperienced Automobile Studies that over a few years and iterations, the corporate has labored to fine-tune the design by way of inverter management and administration of second-order results within the physics of the magnetic discipline. Partly by way of that it’s achieved a ten% effectivity increase versus the earlier technology of its motors, from fourth to its present fifth technology.

Elaphe in-wheel motor for Lightyear 0

By the point Elaphe will get to manufacturing in excessive quantity, which it sees as round 2030, it’s focusing on a 95% effectivity, on a battery-to-wheel foundation, based mostly on freeway driving.

Its design makes use of everlasting magnets, however Gotovac says that the corporate has already confirmed that by 2030 it will likely be in a position to bypass the usage of heavy rare-earth supplies, protecting to lighter rare-earths as a substitute and lowering the environmental footprint.

“We consider that after in-wheel motors are adopted there will even be variations with out everlasting magnets on the low finish of the market,” he added. “However it would deliver some weight penalty.”

Unsprung mass isn’t such a giant deal

In-wheel motors improve the quantity of unsprung mass (all of the mass not supported by the suspension), which auto engineers and insiders routinely declare makes experience and dealing with a lot more durable to tune and complicates security.

It’s merely not as vital of a difficulty as some automobile engineers paint it to be, in line with CTO Gotovac. That’s as a result of wheels and tires, together, are fairly heavy; add an in-wheel motor and also you’re in no way doubling or tripling the load, he defined to Inexperienced Automobile Studies. You’re boosting it by about 30% when figuring within the brakes and all of the ancillary items. Think about objects which are redundant for in-wheel motors and the acquire in unsprung mass might be as little as 35 kilos per wheel versus an inboard motor setup.

And including in-wheel motors on the entrance wheels is a neater approach so as to add hybrid propulsion whereas sustaining security, argued Gotovac. “When you have a automotive which has been engineered and crash-tested and also you need to hybridize it, it’s important to redo all of the crash-testing,” he mentioned. “However in the event you put in-wheel motors in, you don’t should redo all of the crash-testing, as a result of truly the construction in entrance, it will likely be the identical…and in the event you’ve carried out the engineering proper the wheels are simply going to carry onto the remainder of the construction.”

Elaphe’s items are designed to outlive minor collisions, and it signifies that the physique doesn’t want a crash construction designed round incompressible powertrain items.

Lordstown Endurance

Sturdiness work already carried out on in-wheel motors?

What makes in-wheel motors essentially totally different than present inboard motors is that the motor’s rotor spins instantly with the wheel and its stator acts because the hub. Due to this, they’re topic to greater ranges of vibration and highway shocks, however Elaphe’s Gotovac insists that sturdiness is now not a priority. Lately it has pushed its full validation cycle for the automobile lifetime of its motors out to 300,000 miles, from the earlier 150,000 miles.

Lordstown Motors would have supplied that real-world proof of sturdiness for Elaphe, in its Ohio-built Lordstown Endurance electrical pickup, utilizing U.S.-built motors from the Slovenian firm—if it weren’t for Lordstown’s demise in June 2023.

As Gotovac emphasised, the design of the motor that Elaphe nonetheless follows was absolutely validated within the Endurance, however it was a special software as Elaphe itself didn’t have something to do with the inverters, which permit a finer degree of motor management. In a drive of the Lordstown Endurance, Inexperienced Automobile Studies didn’t have any problem with motor response, experience, or dealing with of the electrical truck.

2023 Lordstown Endurance

Certainly one of Ford’s prime EV executives, Darren Palmer, informed Inexperienced Automobile Studies in 2021 that it nixed in-wheel motors as a chance within the F-150 Lightning electrical truck over issues about sturdiness. And Aptera dropped in-wheel motors for its production-bound three-wheeler in what gave the impression to be a difficulty not with any of these issues however with price.

At current, there are some, however comparatively few, examples of mainstream fashions that supply these motor sorts. China’s Dongfeng, in 2023, claimed to be constructing the world’s first passenger automotive with in-wheel motors—powering the rear wheels in that case, provided by Protean Electrical.

Within the meantime, in-wheel motors proceed to appear like the longer term, albeit a future with none vital present-day dedication—and loads of false begins. Maybe backing up Elaphe’s claims that they’re one of the best answer for the longer term, Hyundai and Toyota have continued to develop their very own in-wheel motors, or no less than stay concerned of their growth.

Lightyear with Elaphe motors

In-wheel motors stay mass-market-bound

As Elaphe’s Gotovac defined to Inexperienced Automobile Studies at CES, the corporate sees area of interest high-performance functions like Sonic 1 as an essential step in getting the phrase out about in-wheel motor expertise and the way it can carry out to extremes. But it surely has bigger-picture ambitions on the inexpensive finish of the market.

That is the fifth technology of Elaphe’s motors and it’s been concurrently working towards greater energy density and higher efficiency whereas additionally maintaining a tally of how the tech can really be utilized to the mass market.

Gotovac mentioned that whereas promoting automakers on the thought of in-wheel motors for mass-market EVs has confirmed difficult, the expertise can doubtlessly pay a lot higher dividends.

“We’re in a position to develop this power-dense design that we’ve into one thing that’s cost-effective for a automotive that doesn’t should be as highly effective,” he defined. “In the event you’re utilizing much less materials to get extra energy out of it, and in the event you’re not utilizing unique supplies, then your potential for price is best than the earlier technology.”

Aptera with Elaphe motors

In-wheel motor potential: Journey, dealing with, id

Elaphe’s Sonic 1 motor system is designed to make use of an inverter from its official companion McLaren Utilized Applied sciences, with software program developed with that agency—and the important thing to a few of these particular management methods is the software program.

However Elaphe emphasizes that the potential for in-wheel motor tech rests on rather more than energy supply. After getting it at every wheel, all kinds of alternatives come up for the motors to take an lively position in: experience, dealing with, stability management, and even communication to the motive force.

Aptera with Elaphe motors

Basically, one of many key benefits of Elaphe’s in-wheel motor expertise quantities to this, Gotovac defined: It’s able to blipping torque supply—as much as its peak torque supply—virtually instantaneously, extra exactly than an automaker might with brakes, and in a extra excessive approach than automakers would ever dare with an inboard motor due to driveshafts and CV joints.

Permitting roll management to be dealt with by the in-wheel motor system, Gotovac says, would permit automakers to get rid of bodily roll bars and their constraints. When you have a motor at every nook, coordinated by a central pc, it’s like having “only one brake within the center…you are feeling very secure while you get on ice,” Gotovac defined, or the motors can squeeze at various ranges with simply the precise timing in order to supply roll management.

Elaphe is presently working towards a really fast 10-kHz modulation cycle and a response time of simply 4 milliseconds for full torque supply of its motors. It takes the quickest inboard motor methods 20 occasions as lengthy to reply, Gotovac claimed, and even then they gained’t be capable of present near full torque. “So meaning we actually can management with very excessive bandwidth, a variety of drive,” he mentioned, inserting with a smirk: “So we will get very attention-grabbing results.”

These results might be fairly refined, he says—like engineering some vibration or tonality again into the driving expertise. “We are able to generate vibration to be able to get a sense within the automotive which is engineered however nonetheless genuine,” he mentioned, or have the motors generate security alerts, play songs, or emulate combustion engines—serving a goal not not like what Stellantis has engineered for the Dodge Charger Daytona EV.

All of these are issues you’ll be able to’t do with an inboard-motor EV as a result of there are too many different elements with the driveshafts and suspension, and issues over sturdiness or the harmonics of the gear system.

2024 Dodge Charger Daytona

The longer term: EVs constructed on platforms for in-wheel motors

None of this tech might be absolutely realized, Gotovac admits, till we get a brand new form of EV, conceived from the beginning for in-wheel motors. Enabling their potential is a “vehicle-level problem,” he says, and in-wheel motors will solely make the automobile rather more environment friendly if it’s engineered from the bottom up for the tech.

If automakers are up for taking part in this lengthy recreation with Elaphe, it believes it may decrease general automobile price by 20% and increase vary and effectivity by 20%—together with whole-vehicle design, aerodynamics, chassis controls, and the load of the automotive. “That’s the place the massive potential lies,” Gotovac mentioned.

No main automaker has signed up but. And what precisely retains automakers from committing to in-wheel motors on large, mass-market, inexpensive EV initiatives appears like a basic chicken-or-egg dilemma.

Rivian and Volkswagen Group electrical structure and software program stack

Attending to the 20% effectivity increase requires a giant funding and dedication that goes past the provider, lamented Gotovac, together with {an electrical} structure meant to accommodate it. “On the part degree we will exhibit somewhat little bit of effectivity enchancment, however not sufficient for them to make a $5 billion funding,” he added, summing up the predicament.

Gotovac requested rhetorically: “What’s the step in between that will get them to consider on this system, in order that they engineer that new platform? That’s the factor…”

It’s what drew my consideration again to the Sonic 1 motor unit on the pedestal, prepared within the meantime to create an Italian unique that, maybe, the tech-savvy will acknowledge for all its firsts.