In February, I had the uncommon alternative to witness firsthand probably the most bold transformations in BMW’s historical past. Hidden behind the model’s iconic headquarters and museum, the Munich plant is present process a large modernization effort that can fully reshape how BMW builds automobiles within the coronary heart of its hometown. This manufacturing unit—one in every of BMW’s longest-running manufacturing websites—has been in operation since 1922, and by 2027, it can produce solely totally electrical automobiles, making it one of many firm’s first crops devoted solely to Neue Klasse manufacturing.

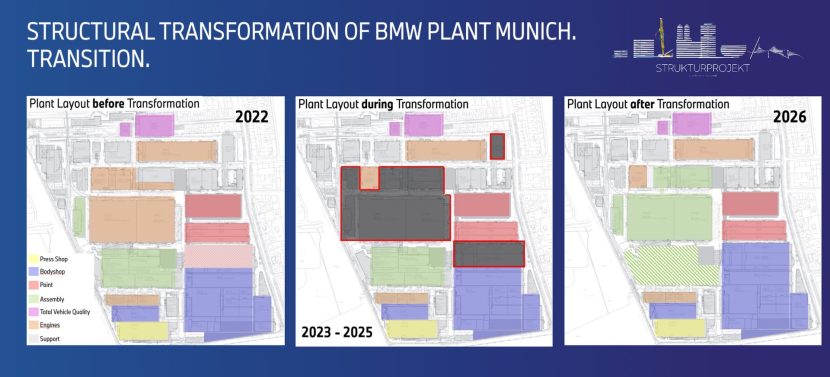

In contrast to BMW’s brand-new manufacturing unit in Debrecen, Hungary, which was designed from the bottom up for the Neue Klasse EV platform, the Munich facility have to be rebuilt from inside, whereas sustaining full-scale manufacturing. The problem is gigantic: BMW is tearing down and rebuilding one-third of the whole plant with out stopping manufacturing. Every single day, 1,000 automobiles roll off the road whereas cranes, vans, and employees function round them. The manufacturing unit will not be increasing outward as a result of house limitations—it’s rising vertically, with three-story manufacturing buildings changing older buildings.

“We’re not remodeling this plant simply because we’re transitioning to electrical automobiles. The plant can already produce electrical automobiles, just like the i4, which makes up 40% of its present manufacturing. The reconfiguration is occurring as a result of the plant is 100 years outdated. Every now and then, you need to rethink manufacturing and develop a brand new construction,” defined Dr. Mohan Noronha, Mission Lead for the Structural Transformation of BMW Manufacturing unit Munich.

Constructing a New Manufacturing unit Whereas Maintaining the Previous One Operating

The transformation of the Munich plant is not only about introducing new expertise—it’s about doing so whereas holding the manufacturing unit operational. In contrast to many automotive crops that shut down for in depth retooling, BMW has no such luxurious right here. Town’s dense city atmosphere makes large-scale enlargement unattainable, so the automaker is demolishing and rebuilding sections of the manufacturing unit in phases whereas manufacturing continues.

This course of requires cautious planning and exact logistics. BMW has initiated 13 main relocation tasks to clear house for the brand new buildings. Complete departments, together with engine manufacturing, wastewater therapy, and axle pre-assembly, have been moved to different areas to make approach for the brand new meeting strains. The engine manufacturing division has been relocated to Austria and the UK, marking the top of combustion engine manufacturing in Munich.

With these large shifts, 600,000 tons of fabric have to be dismantled, examined, and both disposed of or repurposed. Laws require BMW to investigate and course of this materials earlier than transferring it off-site, which means massive parts of the manufacturing unit grounds have to be used for momentary storage. In the meantime, 400 vans transfer out and in of the plant each single day, delivering elements for manufacturing and hauling away dismantled buildings.

New, Extra Vitality Environment friendly Buildings

When accomplished, the transformation will introduce 70,000 sq. meters of recent manufacturing flooring house, making the plant extra environment friendly and higher fitted to EV manufacturing. Three new manufacturing buildings are being constructed for meeting and physique store operations, every with three full tales to optimize flooring house. These new buildings will likely be 40% extra power environment friendly than those they substitute, aligning with BMW’s broader sustainability targets.

“We needed to rethink all the things. There’s no room to broaden outward, so we’re constructing vertically. The brand new Last Meeting Corridor has three flooring, every 9 meters excessive—the footprint alone is the dimensions of six soccer fields. And once you step inside, you notice simply how briskly issues are altering. Should you depart for 2 weeks and are available again, new partitions have already gone up,” Dr. Noronha informed us throughout our go to.

Expertise, AI, and Workforce Transformation

Past its structural adjustments, the Munich plant can be adopting new expertise to streamline manufacturing. The brand new physique store will combine 900+ robots, considerably decreasing the necessity for guide labor in welding and meeting processes. AI-powered high quality management techniques will examine automobiles in real-time, minimizing defects and enhancing effectivity. Moreover, automated logistics techniques will substitute conventional forklifts, decreasing human labor in elements transportation.

Regardless of this shift towards automation, BMW will not be decreasing its workforce. The plant at present employs 6,500 folks from over 60 nationalities, and as an alternative of layoffs, BMW is retraining and repositioning workers for brand new roles in EV manufacturing. A brand new Expertise Campus is being constructed to supply steady coaching, making certain that workers stay on the forefront of recent automotive manufacturing.

“We’re not decreasing jobs; we’re coaching our folks for the longer term,” stated Dr. Noronha.

Sustainability and the Way forward for City Manufacturing

The transformation can be pushed by sustainability and group integration. Given the manufacturing unit’s location within the coronary heart of Munich, BMW has dedicated to decreasing emissions, noise, and site visitors congestion whereas enhancing the plant’s visible and environmental footprint. The brand new design incorporates inexperienced areas, and BMW is exploring methods to make elements of the manufacturing unit extra accessible to the general public.

Moreover, logistics are being optimized to attenuate pointless transportation, with elements being delivered on to manufacturing strains as an alternative of passing by a number of areas. These efforts will cut back site visitors across the plant and decrease emissions, making the power extra appropriate with the encompassing city atmosphere.

An Spectacular Achievement in Only a Yr

Strolling by the plant, it was clear—this isn’t only a easy manufacturing unit improve. It is a historic transformation. For over a century, BMW’s Munich plant has been the beating coronary heart of the model’s manufacturing. Now, it’s evolving right into a state-of-the-art EV manufacturing hub, setting the stage for the Neue Klasse fashions that can outline BMW’s future.

Essentially the most outstanding half? BMW is doing all of this with out stopping.