The Fétis Group is launching Kinell, a brand new model representing the group’s low-carbon and automation actions throughout Europe and North America.

Kinell’s ambition is to supply a whole ecosystem of options to assist the vitality transition in off-highway machines, particular autos, skilled marine and electrical energy. This ecosystem will span your entire vitality cycle—from era to storage to consumption.

These vitality options might be complemented by digital providers that optimise asset administration, increase productiveness, and cut back whole possession prices.

In Could, the primary stage of the rollout targeted on the electrification and automation of off-highway machines and particular autos. This initiative brings collectively Fétis Group operations in Germany, France, Spain, and Canada, which beforehand operated below the Dintec title.

In Q3 and This fall 2025, the group will announce further capabilities in options for the decarbonisation {of professional} marine vessels and decarbonised vitality era and storage

In parallel, the group is ramping up funding in increasing its suite of digital and engineering providers.

“Within the 20 years since our system integration enterprise was based, we’ve partnered carefully with OEMs to deliver their machines to life. This functionality is now central to our strategic imaginative and prescient. As we increase geographically and broaden our providing, we’d like a unified worldwide model that displays our ambition and helps our development,” says Oliver Lythgoe, chief advertising and marketing officer of the Fétis Group.

Kinell is optimistic concerning the long-term potential of low-carbon options in its key industries. With the quickly falling value of renewable vitality and downward stress on battery costs, electrification is changing into not solely the lowest-carbon choice but additionally the most efficient and cost-effective over a machine’s lifetime.

Automation can be set for sturdy development, pushed by industry-wide shortages of expert operators and growing calls for for security and effectivity. These tendencies are carefully linked to the shift towards electrification.

For the preliminary providing in off-highway machines and particular autos, OEMs face three key challenges within the shift to low-carbon and autonomous applied sciences, and the corporate says it’s positioned to assist overcome them.

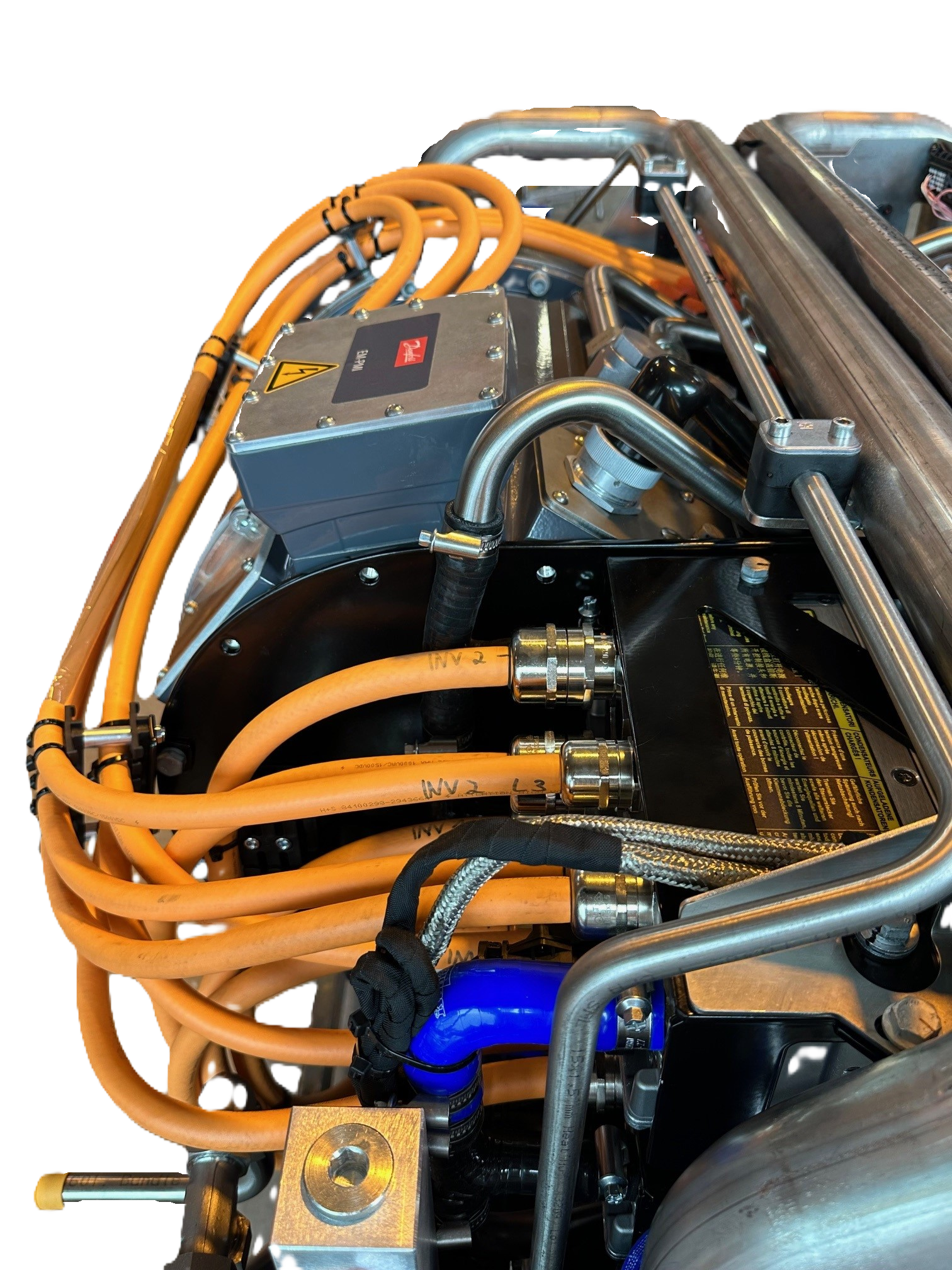

By way of engineering experience, many OEMs lack in-house expertise in high-voltage, high-current electrical architectures. By partnering with Kinell’s engineering groups, OEMs can cut back threat, speed up improvement timelines, and optimise system prices.

Kinell additionally gives engineering providers in controls, software program, mechanical programs, and prototype improvement—designed to enrich and improve OEMs’ inside capability.

Electrification is greater than propulsion. Kinell supplies pre-engineered system options resembling electrical energy take-off drives (ePTO), charging programs, and energy administration platforms, which assist OEMs ship full machines extra effectively.

Software program and management programs for off-highway machines are anticipated to develop dramatically extra complicated over the subsequent 5 years. Prospects demand ever extra productiveness, effectivity, security, and asset administration options. Economically and technically, it is smart for OEMs to combine externally developed, pre-validated software program modules, enabling inside groups to concentrate on what units their machines aside.

Kinell’s software program portfolio will embrace modules for car path planning, autonomous steering, and connectivity options resembling telematics and precision farming.

Whereas the market already gives a variety of electrification elements—batteries, motors, inverters—OEMs nonetheless want dependable, cost-effective sources for application-specific elements. These embrace wiring harnesses, energy distribution items, and machine-specific software program. Kinell delivers these with high quality and responsiveness.

“As we deliver collectively the capabilities of our worldwide groups, we’re uniquely positioned to assist bold OEMs in fixing the hardest engineering challenges. Sure, we have now deep technical experience—however simply as importantly, we’ve confirmed our agility in a fast-changing market. We’re dedicated to investing in our future and serving to OEMs deliver the subsequent era of machines to life,” concludes Lythgoe.

Pictures courtesy of Kinell